What is CFD Analysis? Achieving High-Accuracy Engineering Design with Computational Fluid Dynamics

What is CFD (Computational Fluid Dynamics)?

Computational Fluid Dynamics (CFD) is an advanced engineering method used to analyze the behavior of liquids and gases through numerical calculations performed by high-performance computing systems. CFD simulations allow engineers to accurately predict velocity fields, pressure distributions, temperature gradients, turbulence effects, and heat transfer processes before physical testing is performed.

Today, CFD analysis services have become an essential part of product development and validation processes across industries such as defense, aerospace, automotive, energy, marine, and heavy manufacturing.

How is CFD Analysis Performed?

A professional CFD engineering analysis typically consists of the following stages:

1. Geometry Preparation

The CAD model of the product or system is prepared, and the fluid domain is defined.

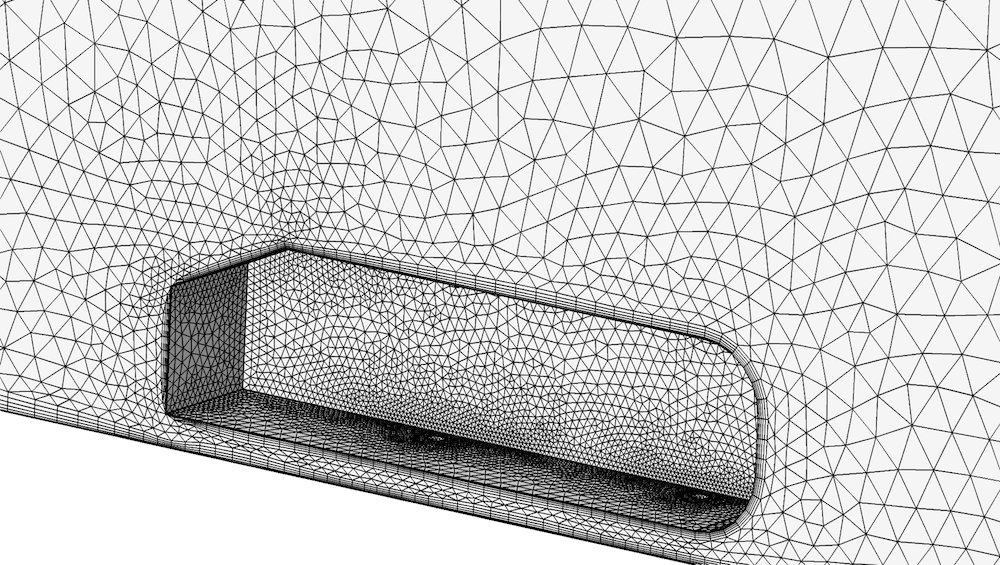

2. Mesh Generation

The geometry is divided into millions of small computational cells to enable numerical solution. Mesh quality is one of the most critical factors directly affecting CFD accuracy.

3. Physics Model Definition

Depending on the analysis requirements, appropriate models are selected:

Turbulence models (k-epsilon, k-omega SST, etc.)

Heat transfer models

Multiphase flow models

Compressible or incompressible flow

Combustion and reaction models

4. Boundary Condition Definition

Inlet velocities, pressure values, temperatures, and environmental conditions are defined.

5. Numerical Solution (Solver)

The Navier–Stokes equations are solved iteratively to compute the fluid flow field.

6. Post-Processing and Evaluation

Velocity, pressure, temperature, and force distributions are evaluated to determine system performance.

Industrial Applications of CFD

CFD simulations are widely used across many industries:

Defense Industry

Missile and projectile aerodynamics

Explosion gas dispersion simulations

Naval hydrodynamic performance analysis

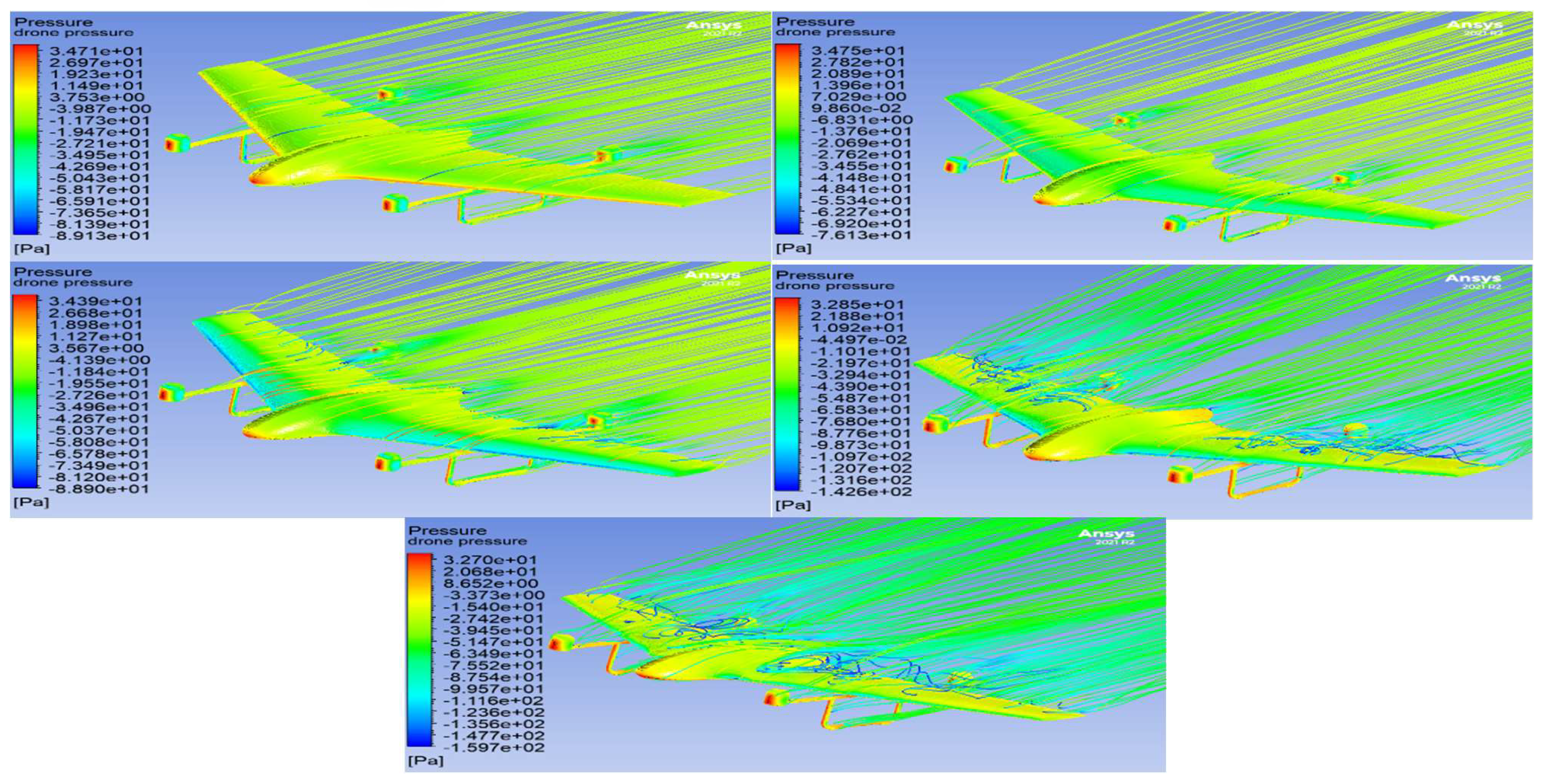

Aerospace

Lift and drag optimization

High-Mach aerodynamic simulations

Automotive

Vehicle aerodynamics and fuel efficiency optimization

Engine cooling and combustion simulations

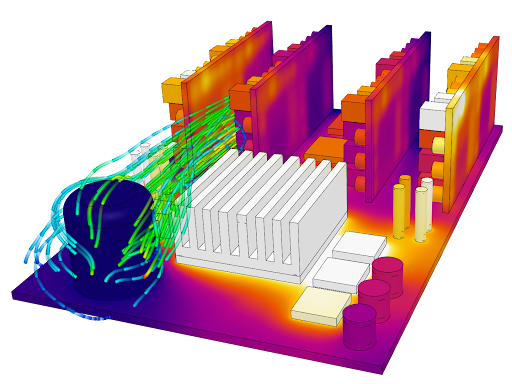

Energy and Industrial Applications

Turbine and pump performance simulations

HVAC airflow analysis

Heat exchanger performance evaluation

Engineering Advantages of CFD Analysis

Professional CFD simulations provide significant engineering benefits:

Reduction in prototype costs

Faster design validation cycles

Performance optimization at early design stages

Improved product safety and reliability

Support for certification and compliance processes

For these reasons, CFD engineering services are considered one of the most critical digital validation tools in modern engineering.

FE-TECH Advanced Engineering CFD Solutions

FE-TECH Advanced Engineering delivers high-end CFD simulation services for defense, automotive, rail systems, and heavy industry projects, including:

Aerodynamic analysis

Internal and external flow simulations

Heat transfer analysis

Multiphase flow simulations

Fan, pump, and turbine performance evaluations

Using advanced simulation platforms such as ANSYS Fluent, FETECH ensures accurate, reliable, and optimized engineering solutions for complex industrial applications.

Computational Fluid Dynamics (CFD) plays a vital role in modern engineering design by enabling accurate prediction of fluid behavior and system performance. With proper meshing strategies, validated turbulence models, and expert engineering interpretation, CFD significantly improves product performance while reducing development costs and testing time.

Contact FE-TECH Advanced Engineering to accelerate your design validation process with advanced CFD simulation solutions.