Part Qualification in Additive Manufacturing: Simulation-Based Verification Approaches

Additive Manufacturing (AM) technologies have created a major transformation in the manufacturing industry over the past decade by increasing design freedom, shortening production times, and enabling the fabrication of high-performance components. However, particularly in metal additive manufacturing processes, part qualification presents significant engineering challenges due to cost, reliability, and certification requirements. This article technically examines how simulation technologies accelerate the additive manufacturing part qualification process and improve production quality.

Why Is Part Qualification Difficult in Additive Manufacturing?

Qualification of metal components produced using Laser Powder Bed Fusion (LPBF) and Electron Beam Manufacturing (EBM) methods is challenging because experimental iterations are both costly and time-consuming. In industries requiring high reliability, such as aerospace, defense, and biomedical applications:

Porosity

Heterogeneous microstructure formation

Lack of fusion defects

Material property variations depending on build orientation and placement

can directly affect the mechanical strength and fatigue performance of parts. The fact that the same component may exhibit different properties under different manufacturing parameters makes purely experimental validation economically impractical.

Simulation-Driven Qualification Approach

Finite Element Analysis (FEA) and process simulations play a critical role in accelerating additive manufacturing part qualification. By analyzing melt pool behavior at the micro scale and deformation and residual stresses at the macro scale:

Process parameters can be optimized

Target melt pool dimensions can be achieved

Distortion compensation can be applied

Geometric accuracy can be improved

The Layered Tetrahedral Meshing (LTM) technology developed in the Ansys Mechanical environment enables accurate layer-based representation of complex geometries, significantly improving part-scale simulation accuracy. A simulation workflow spanning from micro to macro scales allows the root causes of defects to be identified more accurately and enables local optimization of process parameters in critical regions.

Heat Accumulation in LPBF Processes and Its Impact on Qualification

One of the most critical parameters affecting quality in LPBF processes is heat accumulation. Different regions within a component may experience different thermal histories, and residual heat accumulation in certain areas may lead to:

Overheating

Unexpected process behavior

Manufacturing defects

Variations in mechanical properties

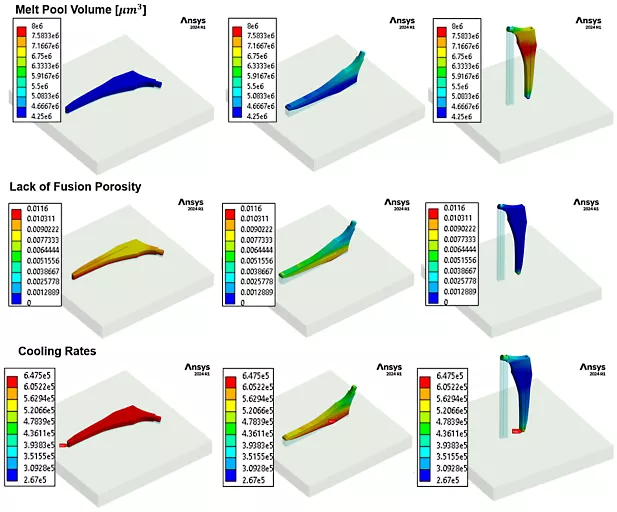

Thermal simulations predict hotspot regions, cooling rates, and melt pool volumes before production, enabling corrective actions such as reducing laser power in critical layers. As a result, production iterations and defect-related costs can be significantly reduced.

Thermal Effects of Multi-Part Printing in Serial Production

In serial production, maximizing build-plate utilization is a key objective. Printing multiple components simultaneously may:

Create thermal interactions between parts

Extend layer scanning time, providing additional cooling intervals

This can reduce hotspot formation in certain regions and increase cooling rates. Simulations allow comparison between single-part and multi-part production scenarios, enabling the determination of the optimal manufacturing strategy.

The Critical Role of Part Orientation in Qualification

Part orientation on the build plate has a direct impact on production quality. Horizontal placement can facilitate heat dissipation but may reduce production capacity, whereas vertical placement can increase production capacity while raising the risk of heat accumulation. Simulations evaluate different orientations in terms of:

Melt pool size

Porosity formation

Cooling rates

Hotspot distribution

to determine the optimal layout. In some cases, controlled overheating can increase melt pool volume and eliminate lack-of-fusion defects. Therefore, process optimization should focus not only on reducing temperature but also on controlled thermal management strategies.

Process Optimization and Automated Design Studies

Integration of modern FEA platforms with optimization modules enables the automatic determination of:

Optimal part orientation

Ideal number of parts to be manufactured simultaneously

Local process parameter optimization in critical regions

Achievement of targeted mechanical properties

Spatial analyses of defect distribution and cooling rates significantly improve quality and reliability, particularly in regions where high stress is expected.

When additive manufacturing part qualification is performed solely through experimental methods, serious limitations arise in terms of cost and time. With multi-scale simulation technologies:

Process parameters can be optimized before production

Hotspot and defect-prone regions can be predicted

Production iterations can be reduced

Certification processes can be accelerated

FE-TECH Advanced Engineering supports companies in achieving more reliable, faster, and lower-cost production processes through advanced engineering solutions in process simulation, structural analysis, and production optimization for additive manufacturing applications.